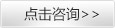

饲料搅拌机http://www.jnxiangfu.com/作为生产加工各种饲料的机械,需要有适应各种不同原材料的性能,只有这样才能满足生产不同类型饲料的需要。温度控制是饲料生产环节中一个特别重要的环节,我们在生产饲料的时候如果对温度没有一个很好的把控的话,其实会对饲料的生产和成品的保存都造成比较大的影响。那么今天我们就来和饲料机械一起来讲一讲,关于饲料的加工中温度控制的那些事。

As the production and processing of feed mixer feed machinery, the need to adapt to a variety of properties of different materials, and the only way to meet the production needs of different types of feed. Temperature control is the feed production chain in a particularly important part in the production of animal feed our time if not a good temperature to control it, in fact, save production and finished feed would have caused relatively large impact. So today we come together to talk and feed machinery, feed processing those things on the temperature control.

饲料搅拌机生产加工过程中,饲料温度的控制尤为重要,特别是高温的夏季,周围环境加上加工车间饲料机械设备的散热,导致颗粒饲料温度居高不下。而遇上阴雨天气,高温高湿必然导致饲料结块,甚至霉变。这不仅给饲料厂造成经济损失,也为养殖户带来安全隐患。

Feed mixer production process, the feed temperature control is particularly important, especially in the summer heat, the surroundings plus feed processing plant machinery and equipment cooling, resulting in high temperature pellets.The case of rainy weather, high temperature and humidity will inevitably lead to feed caking, even mildew. This not only caused economic losses to the feed mill, but also a security risk for farmers.

要保证饲料搅拌机http://www.jnxiangfu.com/冷却器良好运转。逆流式冷却器的正常工作,对降低料温起着至关重要的作用,适当加大风机的转速能够使饲料快速冷却,同时抽风口要进行定期清理,以保证通风量的稳定,控制温度还有别的方面需要注意,因此我们认为,在饲料机械生产加工的过程中,最好是有人可以全程监控,才能及时处理出现的各种问题。

To ensure the smooth functioning of the cooler feed mixer. Counterflow cooler to work on reducing the material temperature plays a vital role, appropriate to increase the fan speed enables rapid cooling of feed, while exhaust ports to

be cleaned regularly to ensure the stability of ventilation, temperature control also there are other aspects to note, therefore we believe that in the process of production and processing of feed machinery, preferably someone can

monitor the entire process, in order to deal with emerging issues in a timely manner.