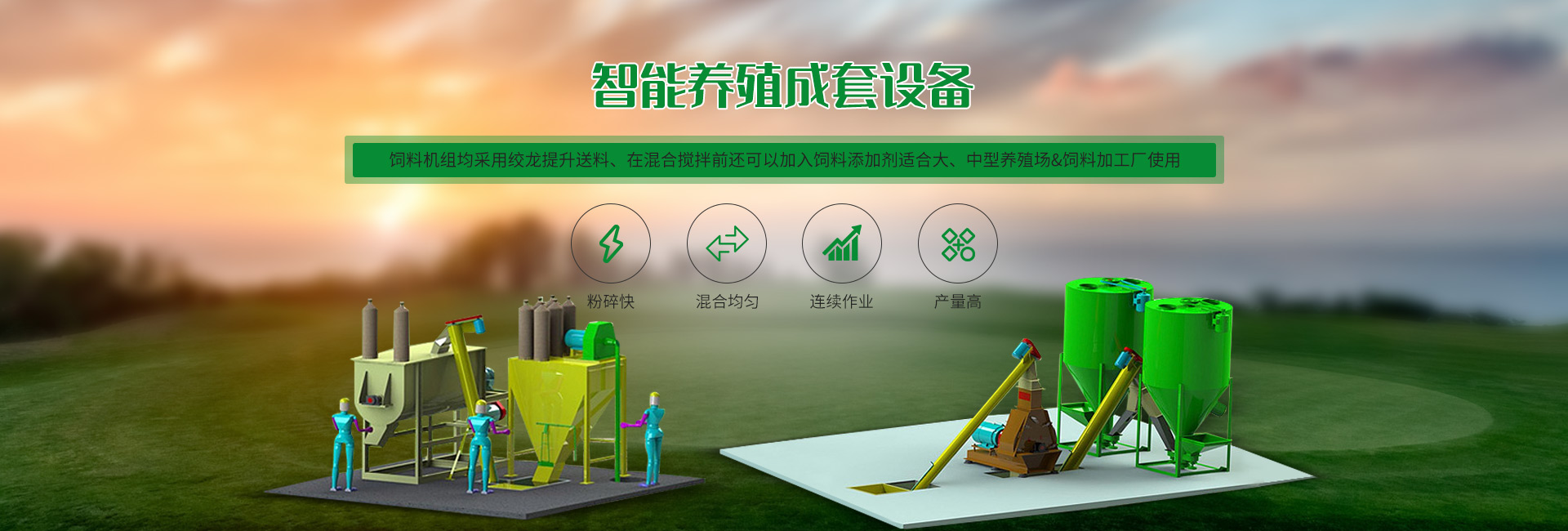

我们首先要做到的就是叫提供合理的压辊的驱动力,饲料搅拌机http://www.jnxiangfu.com/压辊的驱动力是颗粒系统的主要推动力,压辊的驱动力过大机器的运转的速度就会越快,但是当驱动力的能量到达一定的高度之后,会对机器的零部件在超负荷的形式下工作,从而导致饲料搅拌机的损坏,这样生产用原材料含水量就会过多,所以一定要控制好饲料搅拌机的进料驱动力。

We first want to do is called a driving force reasonable roll, the driving force of the pressure roller feed mixer is the main driving force of the particle system, the driving force of the pressure roller of excessive speed of the machine operation will be faster, but when the energy reaches a certain height of the driving force, will machine parts in the form of work overload, resulting in damage to the feed mixer, so that the water content of the raw materials used would be too much, so be sure to control the feed mixer the feed driving force.

最后一点就是要注意合理的饲料搅拌机http://www.jnxiangfu.com/原材料的速度,只有控制好原材料的粒度才能最大限度的把握饲料的成品合格率,得到的成品饲料含水率也是最低的。

The last point is to pay attention to a reasonable rate of raw material feed mixer, only control the particle size of the raw material in order to maximize the rate of qualified products to grasp feed, finished feed moisture content was also the lowest.